|

| |

What is GRP : Glass

reinforced Plastics

( Also known as Fibreglass or FRP- Fiber reinforced polymer)

Main

Article page |

Beauty articles

|

Health page |

Computers|

Diseases |

Education |

Entertainment |

Family

Business |Fitness|

Fruits and Vegetables

|

Jobs |

General |

Personality|

Technology

|

Tourism |

Sports

House Plans |

House Loans |

Real Estate|

Vaasthu

Shastra|

Construction Tips

Engineering page

| Interior Design |

Property Buying Tips |

Renting Tips |

Journals /

Magazines

Known as glass-reinforced

plastic (GRP)

in Britain, fibre-reinforced

plastic (FRP)

in the USA, or by the trade name fibreglass (after the manufacturing company

Fibreglass Ltd.), GRP has been used for a wide range of applications from car

body panels and boat hulls to furniture and tennis rackets. It has the virtue of

a good weight to strength ratio, rust resistance, and ability to be moulded in a

wide variety of ways.

Early use of GRP in automobile manufacture included the roof of

the Citroen DS (1955)

and the body panels of the Chevrolet Corvette (1953).

From the 1970s improved production processes engendered more widespread uses in

architecture and interior design, whether in terms of weather resistant details

and services or bathrooms.

GRP is composed of strands of glass. Each individual glass fibre

is very fine with a small diameter, and they are woven to form a flexible

fabric. The fabric is normally placed in a mould, for instance a mould for a

canoe and polyester resin is added, followed by a catalyst (to speed up the

reaction). The process is repeated so that there are many layers of fibre glass

and resin and allowed to dry/cure. The resulting material is strong and light.

Glass Reinforced Plastic can be sanded for a smooth finish and painted.

Glass reinforced plastic is lightweight and has good thermal

insulation properties. It has a high strength to weight ratio, making it useful

for the production of products such as water tanks, surfboards, canoes, small

boat hulls and similar products. The new European fighter plane, called ‘Eurofighter’,

has an airframe which includes 12% glass reinforced plastic.

PROPERTIES

An individual

structural glass fiber is both stiff and strong in tension and compression—that

is, along its axis. Although it might be assumed that the fiber is weak in

compression, it is actually only the long aspect ratio of the fiber which makes

it seem so; i.e., because a typical fiber is long and narrow, it buckles

easily.[3] On the other hand, the glass fiber is weak in shear—that is, across

its axis. Therefore if a collection of fibers can be arranged permanently in a

preferred direction within a material, and if the fibers can be prevented from

buckling in compression, then that material will become preferentially strong in

that direction.

Continued down...

Articles:

-

Construction: What is

GRP or fibreglass ?

-

Interior design : What is

MDF-Medium Density Fiberboard. ?

-

Construction: What is epoxy

based paint?

-

Guidelines and tips: To find a reliable Builder or

Contractor

-

Guidelines & tips

before you start house construction

-

What is top-up housing loan ?

-

Home improvement tips:

Wallpaper for interiors

-

Benefits of rainwater

harvesting in homes

-

Tips & guidelines: Electricity Saving at home

-

Coming Up With Landscaping Ideas

-

How to set out a building on site

-

Interior design: The Rebirth of Wallpaper

-

What

is

Green Building ?

-

What is Domestic biogas plant ?

-

Why home insurance is very important in India?

-

How To Install a Home Wind Turbine

to get energy

-

How to Install Electric Wiring

-

Significance of Home Plumbing

-

Should I buy or rent? A simple calculation

-

Easy Landscaping Tips for Beginners

-

Construction technique:

Rapidwall technology

-

Buying a flat? Don't get carried away by the sample

-

30-storey hotel built in just 15

days

-

Is it worth buying an old

house

-

House plans, home plans, plans, residential plans

-

House Loans, home loans, where to get housing loan

-

How do loans work, the basic concepts of loans

-

Construction Tips, construction guide lines,

-

house rental tips, rental tips, renting properties

-

Real Estate

-

Flooring

-

What is Reverse Mortgage

-

Guidelines to purchase residential properties

-

Lotus-shaped 91 feet prayer hall in kerala

-

What is Interior Design, interior desings, resources

-

Interior Design Colleges

-

Interior Design- Bed Rooms

-

Interior Design- Bath Rooms

-

Kitchen Designs, kitchens

-

Modern Architectural Design Softwares

-

Landscaping Designs landscape architectures

-

-

|

|

Furthermore, by laying multiple layers of fiber on top of one another, with each

layer oriented in various preferred directions, the stiffness and strength

properties of the overall material can be controlled in an efficient manner. In

the case of fiberglass, it is the plastic matrix which permanently constrains

the structural glass fibers to directions chosen by the designer. With chopped

strand mat, this directionality is essentially an entire two dimensional plane;

with woven fabrics or unidirectional layers, directionality of stiffness and

strength can be more precisely controlled within the plane.

A fiberglass component is typically of a thin "shell" construction, sometimes

filled on the inside with structural foam, as in the case of surfboards. The

component may be of nearly arbitrary shape, limited only by the complexity and

tolerances of the mold used for manufacturing the shell.

USES

Common uses of fiberglass include high performance

aircraft (gliders), boats, automobiles, baths, hot tubs, water tanks, roofing,

pipes, cladding, casts, surfboards and external door skins.

Fiberglass is an immensely versatile material which combines its light weight

with an inherent strength to provide a weather resistant finish, with a variety

of surface textures.

The development of fiber-reinforced plastic for commercial use was being

extensively researched in the 1930s. It was particularly of interest to the

aviation industry. Mass production of glass strands was accidentally discovered

in 1932 when a researcher at the Owens-Illinois directed a jet of compressed air

at a stream of molten glass and produced fibers. Owens joined up with the

Corning company in 1935 and the method was adapted by Owens Corning to produce

its patented "Fiberglas" (one "s"). A suitable resin for combining the

"Fiberglas" with a plastic was developed in 1936 by du Pont. The first ancestor

of modern polyester resins is Cyanamid's of 1942. Peroxide curing systems were

used by then.

Storage tanks: Storage tanks can be made of

fiberglass with capacities up to about 300 tonnes. The smaller tanks can be made

with chopped strand mat cast over a thermoplastic inner tank which acts as a

preform during construction. Much more reliable tanks are made using woven mat

or filament wound fibre with the fibre orientation at right angles to the hoop

stress imposed in the side wall by the contents. They tend to be used for

chemical storage because the plastic liner (often polypropylene) is resistant to

a wide range of strong chemicals. Fiberglass tanks are also used for septic

tanks.

House

building:

Glass

reinforced plastics are also used in the house building market for the

production of roofing laminate, door surrounds, over-door canopies, window

canopies and dormers, chimneys, coping systems, heads with keystones and sills.

The use of fiberglass for these applications provides for a much faster

installation and due to the reduced weight manual handling issues are reduced.

With the advent of high volume manufacturing processes it is possible to

construct fiberglass brick effect panels which can be used in the construction

of composite housing. These panels can be constructed with the appropriate

insulation which reduces heat loss.

Piping:

GRP and GRE pipe systems can be used for a variety of applications, above and

under the ground.

- Firewater systems

- Cooling water systems

- Drinking water systems

- Waste water systems/Sewage systems

- Gas systems

CONSTRUCTION METHODS

Fiberglass hand lay-up operation

A release agent, usually in either wax or liquid form, is applied to the chosen

mold. This will allow the finished product to be removed cleanly from the mold.

Resin—typically a 2-part polyester, vinyl or epoxy—is mixed with its hardener

and applied to the surface. Sheets of fibreglass matting are laid into the mold,

then more resin mixture is added using a brush or roller. The material must

conform to the mold, and air must not be trapped between the fiberglass and the

mold. Additional resin is applied and possibly additional sheets of fiberglass.

Hand pressure, vacuum or rollers are used to make sure the resin saturates and

fully wets all layers, and any air pockets are removed. The work must be done

quickly enough to complete the job before the resin starts to cure, unless high

temperature resins are used which will not cure until the part is warmed in an

oven. In some cases, the work is covered with plastic sheets and vacuum is drawn

on the work to remove air bubbles and press the fiberglass to the shape of the

mold.

Fiberglass spray lay-up operation

The fiberglass spray lay-up process is similar to the hand lay-up process but

the difference comes from the application of the fiber and resin material to the

mold. Spray-up is an open-molding composites fabrication process where resin and

reinforcements are sprayed onto a mold. The resin and glass may be applied

separately or simultaneously "chopped" in a combined stream from a chopper gun.

Workers roll out the spray-up to compact the laminate. Wood, foam or other core

material may then be added, and a secondary spray-up layer imbeds the core

between the laminates. The part is then cured, cooled and removed from the

reusable mold.

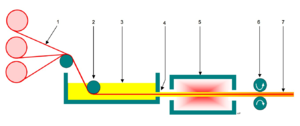

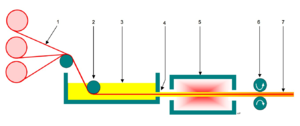

Pultrusion operation

Pultrusion

is a manufacturing method used to make strong light weight composite materials,

in this case fiberglass. Fibers (the glass material) are pulled from spools

through a device that coats them with a resin. They are then typically

heat-treated and cut to length. Pultrusions can be made in a variety of shapes

or cross-sections such as a W or S cross-section. The word pultrusion describes

the method of moving the fibers through the machinery. It is pulled through

using either a hand over hand method or a continuous roller method. This is

opposed to an extrusion, which would push the material through dies. Pultrusion

is a manufacturing method used to make strong light weight composite materials,

in this case fiberglass. Fibers (the glass material) are pulled from spools

through a device that coats them with a resin. They are then typically

heat-treated and cut to length. Pultrusions can be made in a variety of shapes

or cross-sections such as a W or S cross-section. The word pultrusion describes

the method of moving the fibers through the machinery. It is pulled through

using either a hand over hand method or a continuous roller method. This is

opposed to an extrusion, which would push the material through dies.

Chopped strand mat

Chopped strand mat or CSM is a form of reinforcement used in fiberglass. It

consists of glass fibers laid randomly across each other and held together by a

binder.

It is typically processed using the hand lay-up technique, where sheets of

material are placed in a mold and brushed with resin. Because the binder

dissolves in resin, the material easily conforms to different shapes when wetted

out. After the resin cures, the hardened product can be taken from the mold and

finished.

Using chopped strand mat gives a fiberglass with isotropic in-plane material

properties.

Warping

One notable feature of fiberglass is that the resins used are subject to

contraction during the curing process. For polyester this contraction is often

of the order of 5-6%, and for epoxy it can be much lower, about 2%.

When formed as part of fiberglass, because the fibers don't contract, the

differential can create changes in the shape of the part during cure.

Distortions will usually appear hours, days or weeks after the resin has set.

While this can be minimised by symmetric use of the fibers in the design,

nevertheless internal stresses are created, and if these become too great, then

cracks will form.

Examples of fiberglass use

Kayaks made of fiberglass

Surfboards, tent poles

Gliders, kit cars, sports cars, microcars, karts, bodyshells, boats, kayaks,

flat roofs, lorries, K21 Infantry Fighting Vehicle.

Minesweeper hulls

Pods, domes and architectural features where a light weight is necessary.

High end bicycles.

Bodyparts for and entire automobiles, such as the Anadol, Reliant, Quantum

Quantum Coupé, Chevrolet Corvette and Studebaker Avanti, and DeLorean DMC-12

under body.

A320 radome.

FRP tanks and vessels: FRP is used extensively to manufacture chemical equipment

and tanks and vessels. BS4994 is a British standard related to this application.

UHF-broadcasting antennas are often mounted inside a fiberglass cylinder on the

pinnacle of a broadcasting tower

Most commercial velomobiles

Most printed circuit boards used in electronics consist of alternating layers of

copper and fibreglass FR-4.

Large Commercial wind turbine Blades

RF coils used in MRI scanners

Sub sea installation protection covers

Re-enforcement of asphalt pavement, as a fabric or mesh interlayer between

lifts.

Protective helmets used in various sports.

Orthopedic casts

Fiberglass Grating is used for walkways on ships, oil rigs and in factories

( Reference: Wikkipedia)

| |

|

Pultrusion

is a manufacturing method used to make strong light weight composite materials,

in this case fiberglass. Fibers (the glass material) are pulled from spools

through a device that coats them with a resin. They are then typically

heat-treated and cut to length. Pultrusions can be made in a variety of shapes

or cross-sections such as a W or S cross-section. The word pultrusion describes

the method of moving the fibers through the machinery. It is pulled through

using either a hand over hand method or a continuous roller method. This is

opposed to an extrusion, which would push the material through dies.

Pultrusion

is a manufacturing method used to make strong light weight composite materials,

in this case fiberglass. Fibers (the glass material) are pulled from spools

through a device that coats them with a resin. They are then typically

heat-treated and cut to length. Pultrusions can be made in a variety of shapes

or cross-sections such as a W or S cross-section. The word pultrusion describes

the method of moving the fibers through the machinery. It is pulled through

using either a hand over hand method or a continuous roller method. This is

opposed to an extrusion, which would push the material through dies.